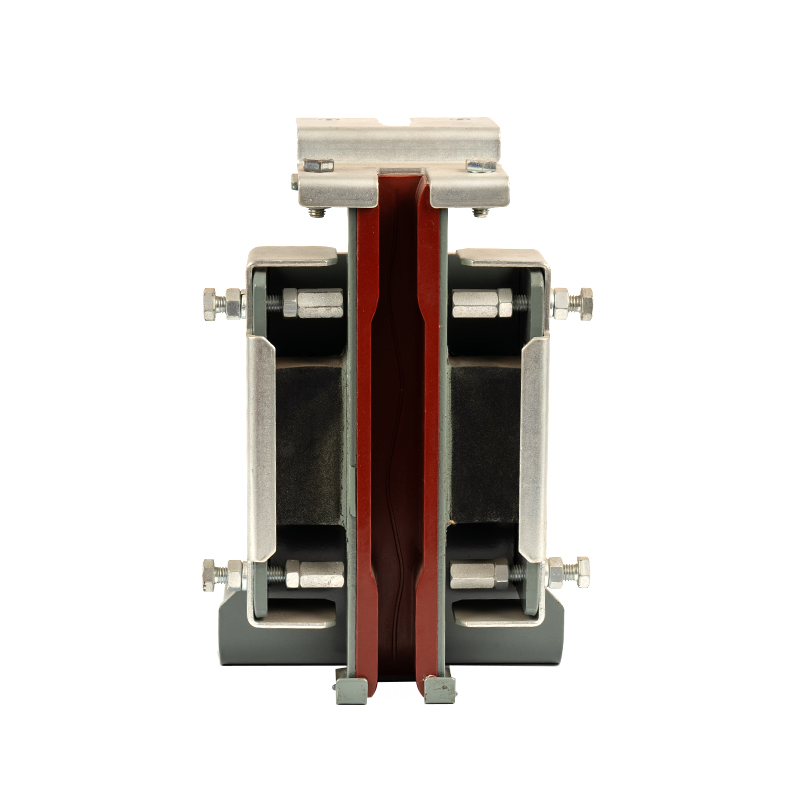

In the industrial field, sliding guide shoes are an important part of mechanical equipment, and their performance directly affects the operating efficiency, stability and service life of the equipment. The material selection of sliding guide rail boots is one of the key factors that determines its load-bearing capacity and service life. This article will delve into the importance of material selection for sliding rail boots and the specific impact of different materials on their performance.

1. The importance of material selection

The material of the sliding guide shoe determines its key properties such as hardness, wear resistance, corrosion resistance, and thermal stability. High-quality materials can not only effectively improve the load-bearing capacity of the sliding guide rail boots, allowing them to maintain stable performance under high-load, high-frequency working conditions, but also significantly extend their service life and reduce damage caused by wear, corrosion, etc. Replacement frequency, thereby reducing equipment maintenance costs.

2. The influence of different materials

Metal material

Metal materials such as steel and cast iron are often used in sliding guide shoes that need to withstand high loads due to their high strength and hardness. However, metal materials are prone to wear and heat during friction, and corresponding lubrication measures need to be taken to reduce friction and wear. In addition, metal materials have poor adaptability to corrosive environments and require additional anti-corrosion measures.

Polymer materials

Polymer materials such as polytetrafluoroethylene (PTFE), nylon, etc. are widely used in sliding guide boots due to their good wear resistance, self-lubrication and corrosion resistance. These materials generate less heat during friction and effectively reduce noise and vibration. However, the load-bearing capacity of polymer materials is relatively low and is not suitable for high load conditions.

composite materials

Composite materials are new materials that combine two or more materials with different properties through physical or chemical methods. By rationally selecting material combinations and preparation processes, sliding guide boots with excellent performance can be obtained. For example, by combining metal with polymer materials, sliding guide shoes can be obtained that have high strength and hardness, as well as good wear resistance and self-lubricating properties. The application of composite materials can significantly improve the load-bearing capacity and service life of sliding guide shoes.

3. Considerations for material selection

When selecting the material of the sliding guide shoe, factors such as the equipment's working conditions, usage environment, and maintenance costs need to be comprehensively considered. For example, in working conditions that need to withstand high loads and high frequencies, metal materials with higher strength and hardness should be selected; in corrosive environments, polymer materials or composite materials with good corrosion resistance should be selected; To reduce noise and vibration, polymer materials or composite materials with good self-lubricating properties should be selected.

English

English 中文简体

中文简体