The Elevator Guide Shoe is a key component in the elevator system. Its main function is to ensure the stability of the vertical movement of the elevator car or counterweight in the guide rail. It reduces the friction between the car and the guide rail by sliding or rolling, and prevents the car or counterweight from tilting, swinging and other unstable phenomena, thereby ensuring the smoothness and safety of the elevator operation.

Structure and composition of elevator guide shoes

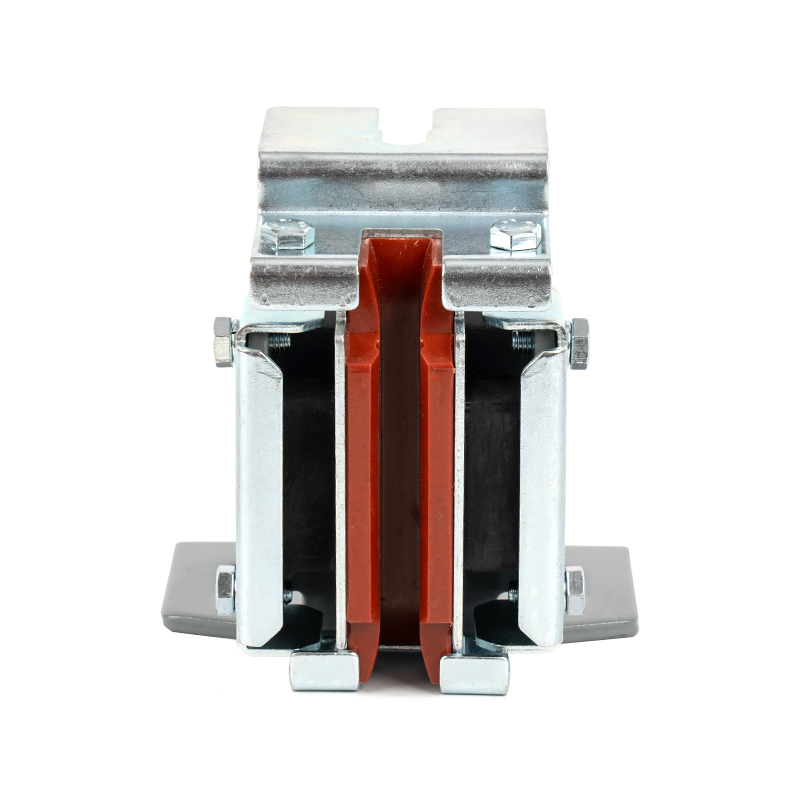

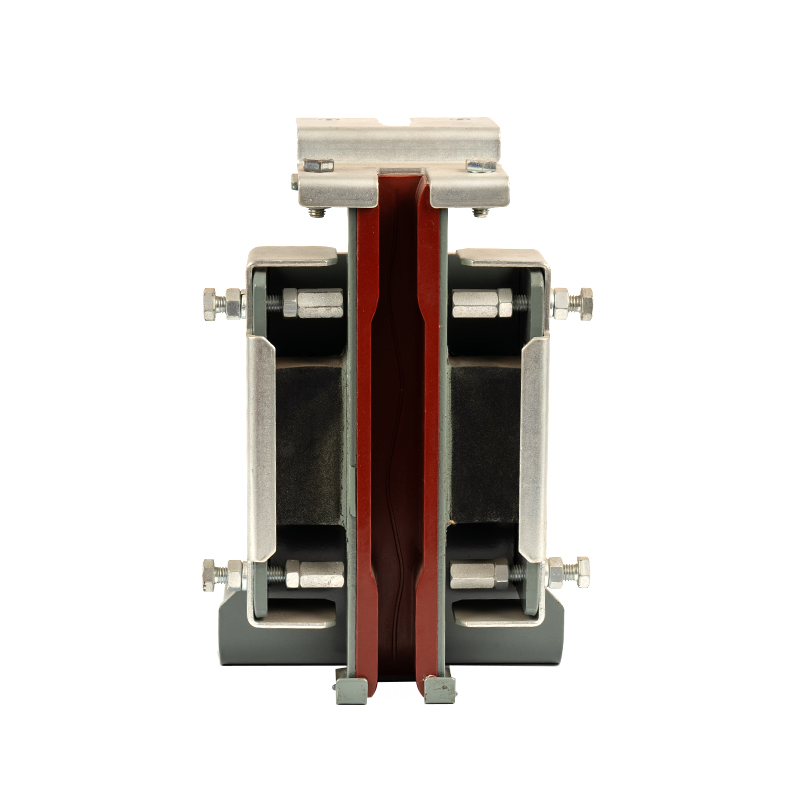

The elevator guide shoe consists of multiple parts, mainly including shoe lining, guide rail body, guide shoe seat and other components. Each component plays a different role and works together to ensure the smooth operation of the elevator. Specifically:

Shoe lining: This is the friction contact part of the guide shoe, which directly contacts the elevator guide rail. Its design and material selection are crucial, which can effectively reduce friction and wear and maintain the smoothness of the elevator operation.

Guide rail body: The guide rail body is the main structure that supports the elevator car and counterweight, ensuring that the vertical track of the elevator does not deviate. The guide shoe contacts the guide rail body through the shoe lining to play a stabilizing role.

Guide shoe seat: The guide shoe seat fixes the shoe lining and the guide rail body, and provides a support structure for the guide shoe to ensure the stability and reliability of the guide shoe.

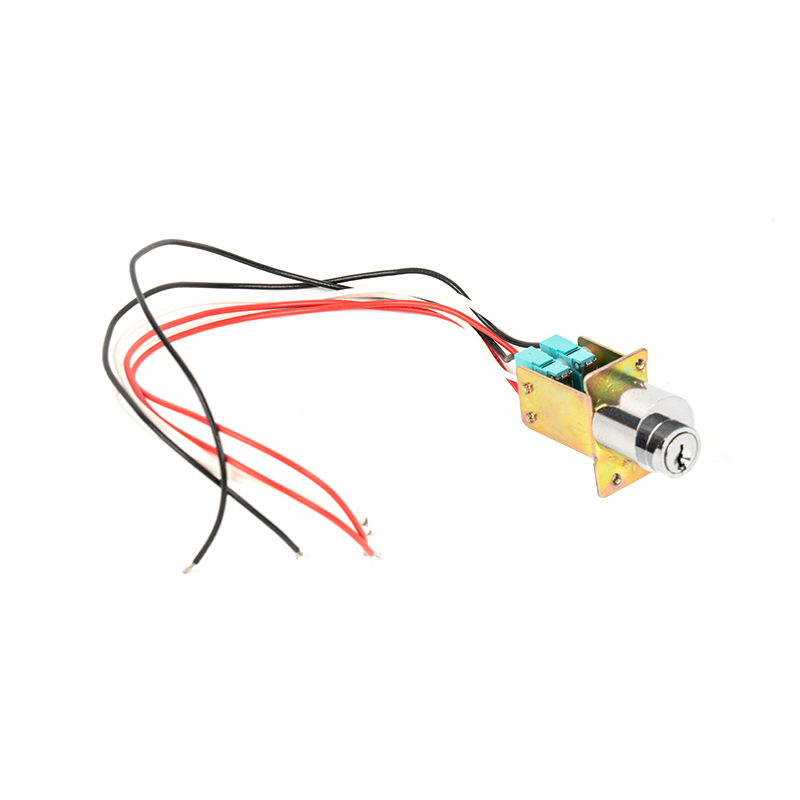

In addition, the oil cup is also a part of the guide shoe, which is installed on the upper part of the guide shoe to reduce the friction between the shoe lining and the guide rail body. By refueling regularly, the oil cup can keep the guide shoe and the guide rail lubricated, reduce friction and wear, and extend the service life of the elevator.

Working principle of elevator guide shoe

The elevator guide shoe ensures that the elevator car or counterweight only moves up and down in the vertical direction through contact with the elevator guide rail to prevent tilting or lateral swing. During the operation of the elevator, the friction between the guide shoe and the guide rail is converted into a stable guiding force through sliding or rolling, ensuring that the car moves smoothly along the vertical track.

Rolling guide shoe: Use rolling elements (such as rollers) to reduce friction, usually suitable for high-load, high-speed elevator systems, providing smoother and more efficient operation.

Sliding guide shoe: Guidance is achieved through sliding contact with the shoe lining, suitable for low-speed and medium-speed elevators, with the advantages of simple structure and low cost.

Importance of guide shoes to elevator stability

The stability of elevator guide shoes directly affects the running quality of the elevator. They ensure the smooth operation of the car or counterweight and avoid deviations caused by uneven guide rails or other external factors. The role of guide shoes is mainly reflected in the following aspects:

Prevent tilting and swinging

During the operation of the elevator, the guide shoes can effectively prevent the tilting or swinging of the car or counterweight. Due to the stable contact between the guide shoes and the guide rails, the movement of the car and counterweight in the vertical guide rails remains straight, ensuring that there is no lateral deviation or imbalance during the operation of the elevator.

Reduce friction and wear

The elevator guide shoes can effectively reduce friction through the contact between their shoe lining parts and the guide rails, avoiding excessive wear of the guide rails and guide shoes caused by excessive friction. Guide shoes made of suitable materials can greatly reduce friction, improve elevator operation efficiency, reduce energy consumption, and extend the service life of elevator components.

Ensure smooth operation of the elevator

The elevator guide shoes help maintain the stability of the elevator car and counterweight, so that the elevator can remain stable when running at high or low speeds. Through precise design and installation, the guide shoe can ensure that the horizontal and vertical movement of the elevator is consistent, avoiding possible vibration or noise problems and improving passenger comfort.

Improve safety

The elevator guide shoe prevents the elevator from accidentally deviating in extreme situations by maintaining the precise docking between the guide rail and the car. Especially when there are certain faults or external interference in the elevator, the guide shoe can maintain the safety of the elevator operation and ensure the stability of the elevator system at critical moments.

Installation and maintenance requirements

Proper installation and regular maintenance are essential for the normal function of the guide shoe. According to the different types of guide shoes, it is necessary to ensure that the upper and lower guide shoes are vertically aligned during installation to avoid deflection, distortion, etc. Especially for fixed sliding guide shoes, the gap between the guide shoe and the guide rail should be controlled between 0.5-2mm during installation to ensure normal friction and movement of the guide shoe.

English

English 中文简体

中文简体