1. The difference between roller contact and sliding contact

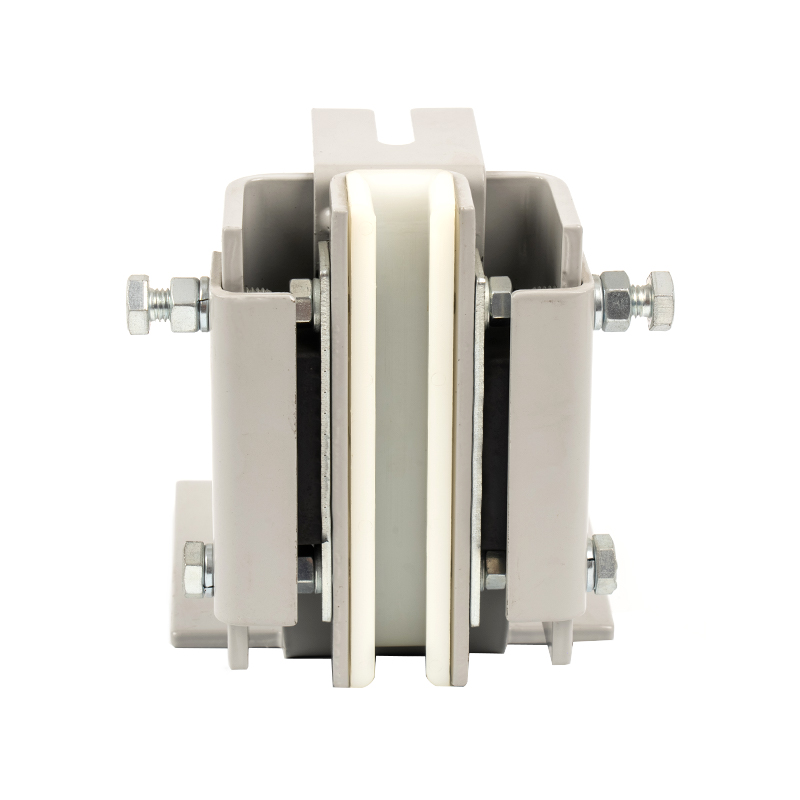

Traditional elevator guide shoes use sliding contact, that is, the movement between the guide shoes and the guide rails is based on friction. This type of contact will generate greater friction, resulting in noise and vibration. The Elevator Roller Guide Shoe contacts the guide rail through rolling contact, using the rotation of the roller to replace traditional sliding friction.

The friction coefficient of rolling friction is much lower than sliding friction, which means that the friction between the guide shoes and the guide rails is significantly reduced during the operation of the elevator. The reduction in friction directly reduces energy losses, thereby reducing noise and vibration caused by friction. Due to the large and smooth contact surface of the Elevator Roller Guide Shoe, the elevator does not produce sharp friction sounds and vibrations like traditional sliding guide shoes during operation, which greatly improves the comfort and quietness of the elevator operation.

2. Reduce vibration between guide shoes and guide rails

The design of the Elevator Roller Guide Shoe not only reduces friction, but also further reduces noise generation by reducing vibration between the guide shoe and the guide rail. In traditional sliding guide shoes, due to large friction, the contact between the guide shoes and the guide rails often produces irregular vibrations, which are transmitted to the elevator car and passengers, resulting in increased noise. The roller guide shoes adopt a rolling contact method, which can distribute the pressure from the elevator car more evenly and avoid irregular vibrations.

In addition, Elevator Roller Guide Shoe usually uses high-precision processing and high-strength materials, making the contact between each roller and the guide rail very even, which further reduces unnecessary vibration and noise. For example, high-quality steel or composite rollers can withstand greater loads, ensuring smoother contact between the guide shoes and the guide rails during elevator operation, avoiding unnecessary impacts and vibrations.

3. Optimization of roller material and structural design

The noise suppression effect of the Elevator Roller Guide Shoe is also closely related to its material and structural design. High-quality roller guide shoes are usually made of wear-resistant and impact-resistant high-performance materials, such as high-strength steel or wear-resistant composite materials. These materials not only have excellent wear resistance, but also can effectively absorb and disperse the vibration generated by the elevator during operation.

4. Noise and vibration control in high-speed elevators

In high-speed elevators, friction and vibration between the elevator car and the guide rails are usually more significant. As the elevator speed increases, the effects of friction and vibration become more prominent. The design concept of Elevator Roller Guide Shoe is to solve the problems of high friction, high noise and strong vibration in high-speed elevators. Because the roller guide shoes can effectively reduce the friction coefficient, it allows the elevator to maintain low noise and vibration levels when running at high speeds.

5. Extend elevator life and reduce maintenance frequency

Elevator Roller Guide Shoe not only improves the comfort of elevator operation by reducing friction and vibration, but also effectively reduces system wear and failure probability. Traditional sliding guide shoes will suffer from high friction for a long time, which will cause wear of the guide rails and guide shoes, thus affecting the stability and safety of the elevator. The roller guide shoes, because of their excellent wear resistance and shock absorption function, can reduce the failure rate of the elevator and extend its service life.

English

English 中文简体

中文简体