1. Application of high wear-resistant materials

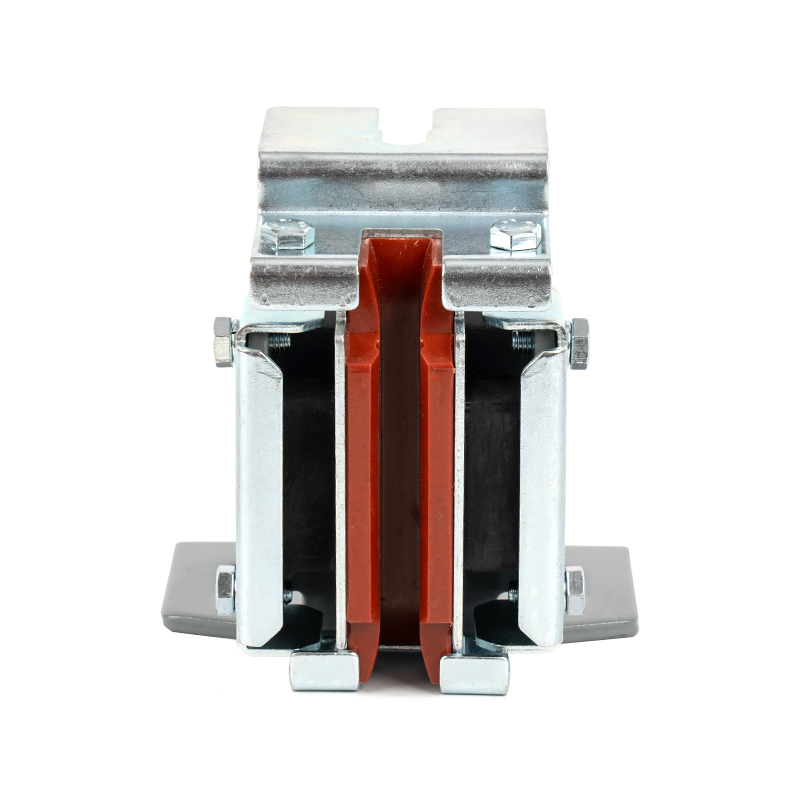

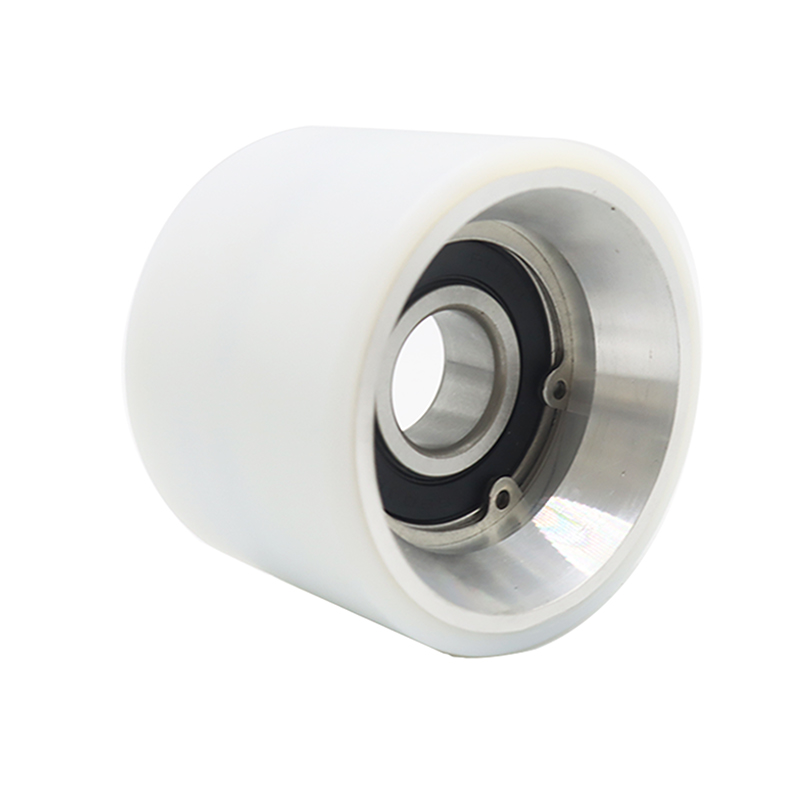

The wear resistance of the Elevator Roller Guide Shoe is first reflected in the choice of its material. Generally speaking, roller guide shoes are usually made of high-strength steel, alloy materials or composite materials. These materials have extremely high wear resistance and impact resistance, and can withstand the huge friction and pressure generated during elevator operation.

Materials with strong wear resistance can effectively prevent friction and wear between the guide shoe and the guide rail, thereby extending the service life of the guide shoe. Since the guide rail of the elevator is in contact with the guide shoe for a long time and bears the weight of the elevator car and passengers, the use of high-strength and wear-resistant materials can effectively reduce problems such as material aging and surface wear, ensuring that the elevator can maintain good stability in high-frequency operation.

2. Reduce friction and wear and improve operational stability

One of the biggest features of the Elevator Roller Guide Shoe is to reduce friction through rolling contact, rather than transmitting power through sliding friction like traditional sliding guide shoes. The friction coefficient of rolling contact is much lower than that of sliding friction. Therefore, the friction generated by the roller guide shoe during the operation of the elevator is significantly reduced, thereby effectively slowing down the wear between the guide shoe and the guide rail.

Reducing friction not only reduces energy loss and heat generation, but also effectively avoids noise and vibration problems caused by excessive friction. This smooth movement can greatly reduce the wear rate of the guide shoe, thereby extending the service life of the elevator. Especially in high-speed elevators and heavy-load elevators, the wear resistance of the Elevator Roller Guide Shoe can ensure that the elevator remains in good operating condition under long-term high-load operation.

3. Improve the long-term stability of the elevator system

In long-term use, elevators will experience frequent up and down operations and large loads. Traditional sliding guide shoes are prone to wear and deformation due to high friction with the guide rail, resulting in unstable elevator operation, increased noise and even failure.

High wear resistance enables the Elevator Roller Guide Shoe to withstand large loads without obvious wear or deformation. Even in high-rise buildings, where elevator systems need to run frequently, roller guide shoes can still ensure good contact between the elevator car and the guide rails, keeping the elevator running smoothly. This is especially important for elevator systems that need to run 24 hours a day, because these elevator systems are usually under long-term heavy load operation, and the wear resistance of roller guide shoes can significantly reduce the failure frequency of elevator systems.

4. Reduce maintenance frequency and reduce maintenance costs

The wear-resistant Elevator Roller Guide Shoe can effectively reduce failures and maintenance needs caused by wear. Traditional sliding guide shoes wear quickly during long-term operation and need to be replaced or maintained regularly. The roller guide shoes can significantly reduce the maintenance frequency of the elevator system due to the high wear resistance and low friction coefficient of their materials.

Every maintenance in the elevator system requires stopping the system for inspection and replacement of parts, which not only affects the efficiency of the elevator, but also increases the maintenance cost. By using the highly wear-resistant Elevator Roller Guide Shoe, the maintenance cycle of the elevator can be greatly extended, thereby reducing the downtime and maintenance cost of the elevator. Especially in large commercial buildings and high-rise residential buildings, elevators are important means of transportation. Their high frequency of use has high requirements for maintenance costs. The wear resistance of roller guide shoes can effectively reduce these costs.

5. Improve elevator safety and comfort

In addition to extending service life and reducing maintenance costs, the wear-resistant Elevator Roller Guide Shoe can also improve the safety and comfort of elevators. By reducing the friction between the guide shoe and the guide rail, the roller guide shoe can effectively avoid the situation of unstable elevator movement or deviation from the guide rail caused by guide shoe wear.

In high-rise buildings or ultra-high-speed elevators, stability and safety are the factors that passengers are most concerned about. The wear resistance of the roller guide shoe can ensure that the elevator can still run smoothly even at high speed and high load, avoiding elevator failures and accidents caused by guide shoe wear or failure, thereby improving the overall safety of the elevator.

English

English 中文简体

中文简体